Do your field technicians, operators and engineers need help to diagnose and repair complex or new faults? Does your frontline team arrive onsite only to discover they need extra support? Are your manuals bulky or difficult to navigate making it harder to get the job done?

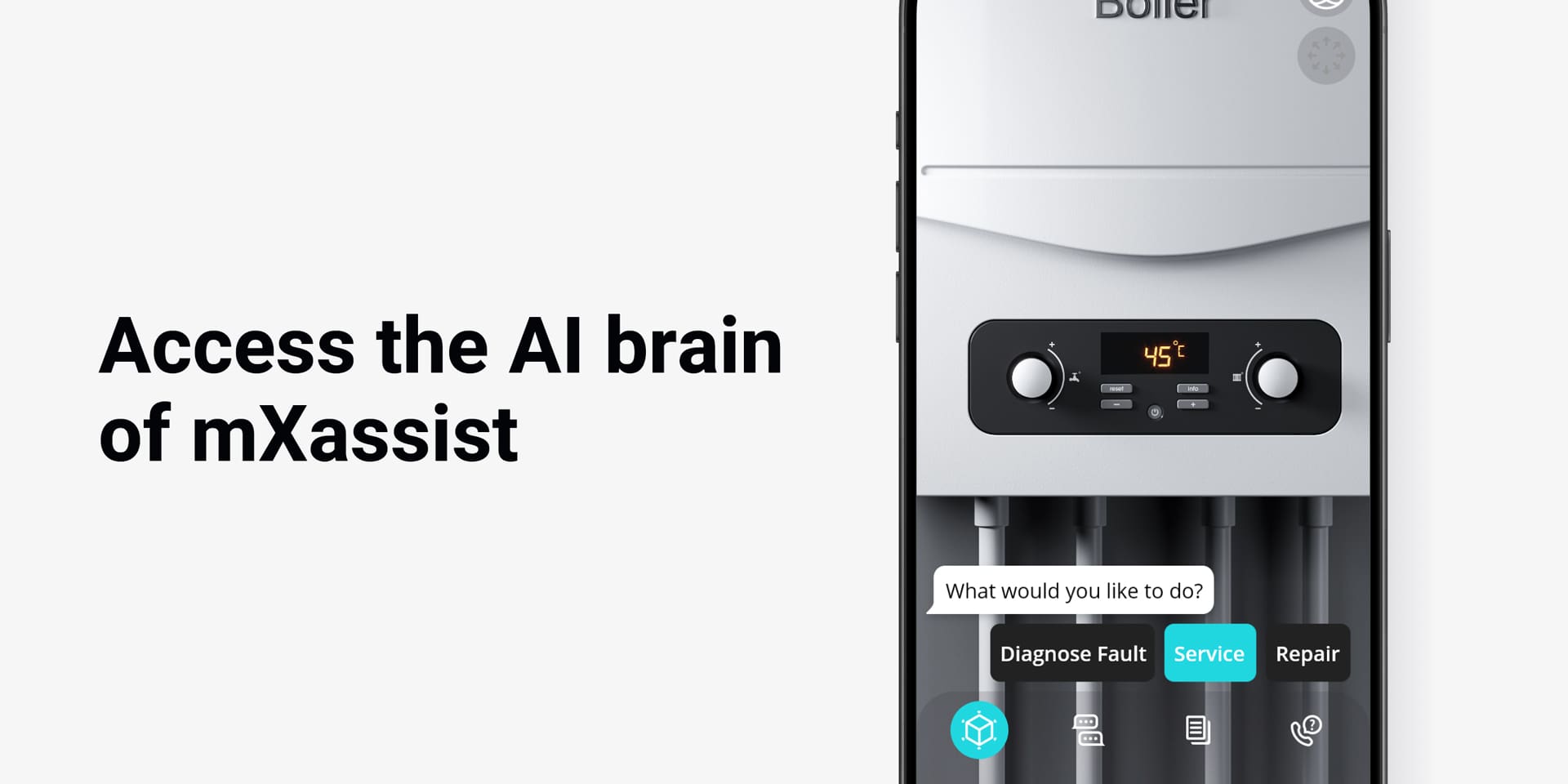

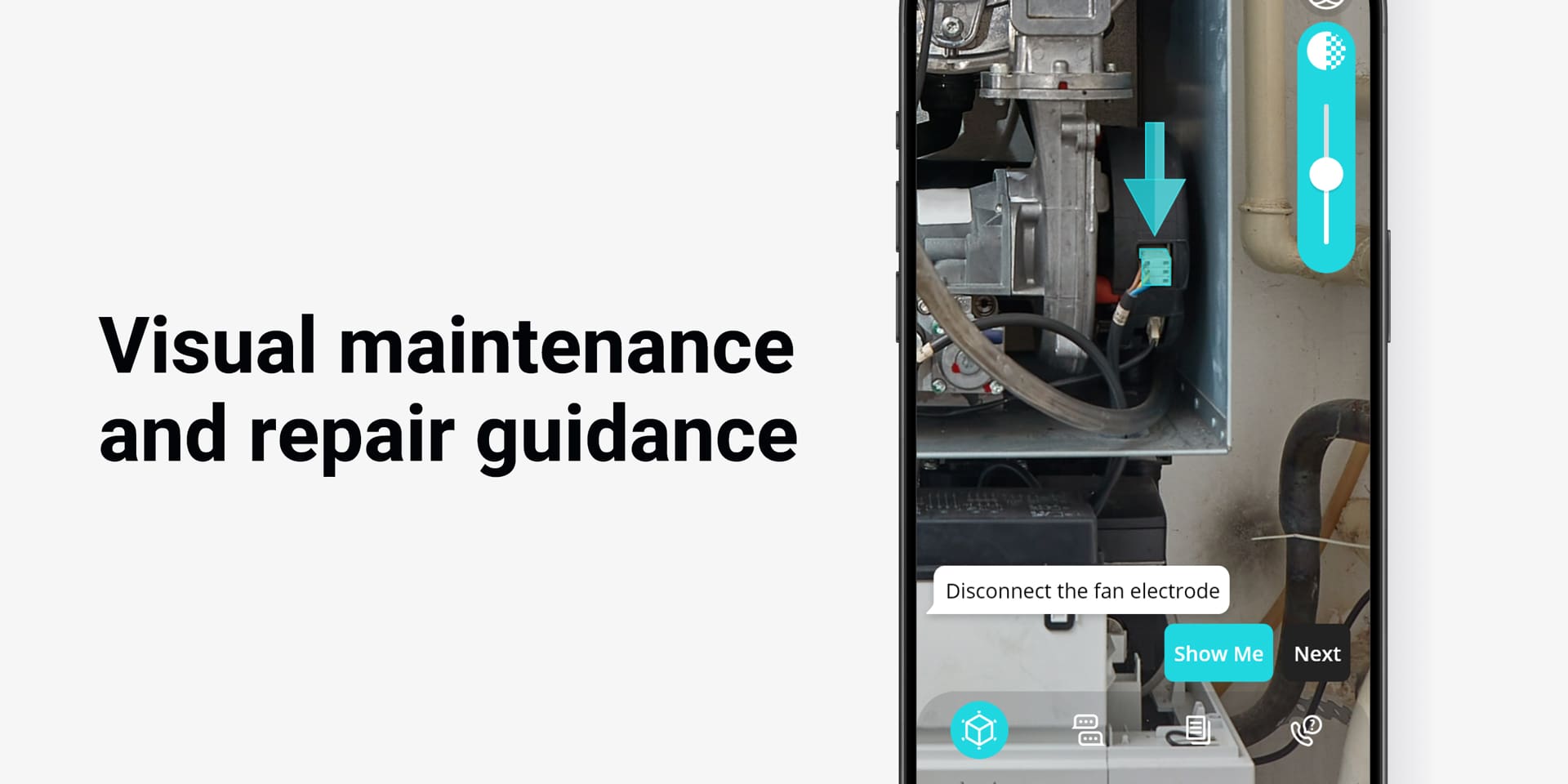

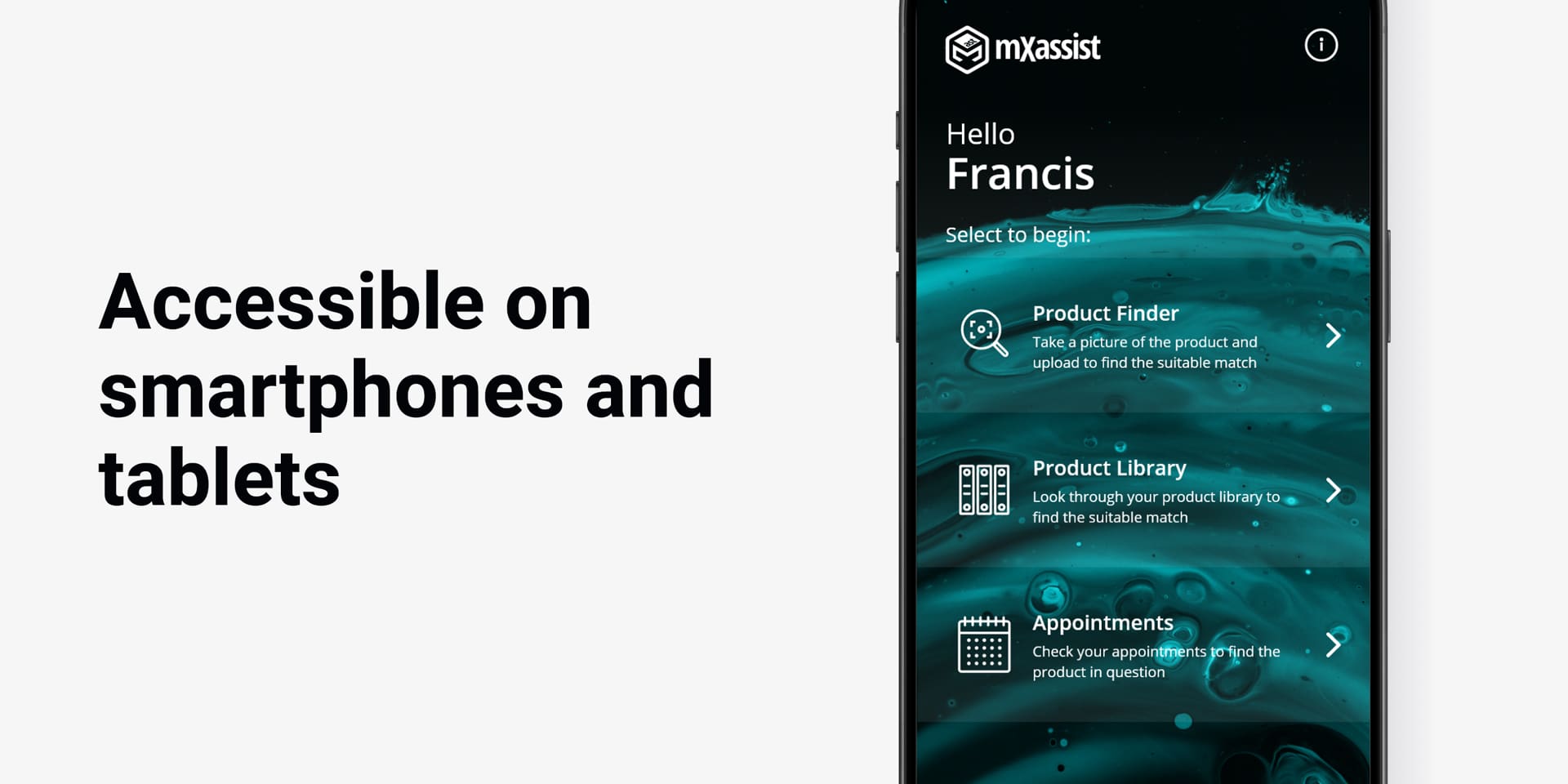

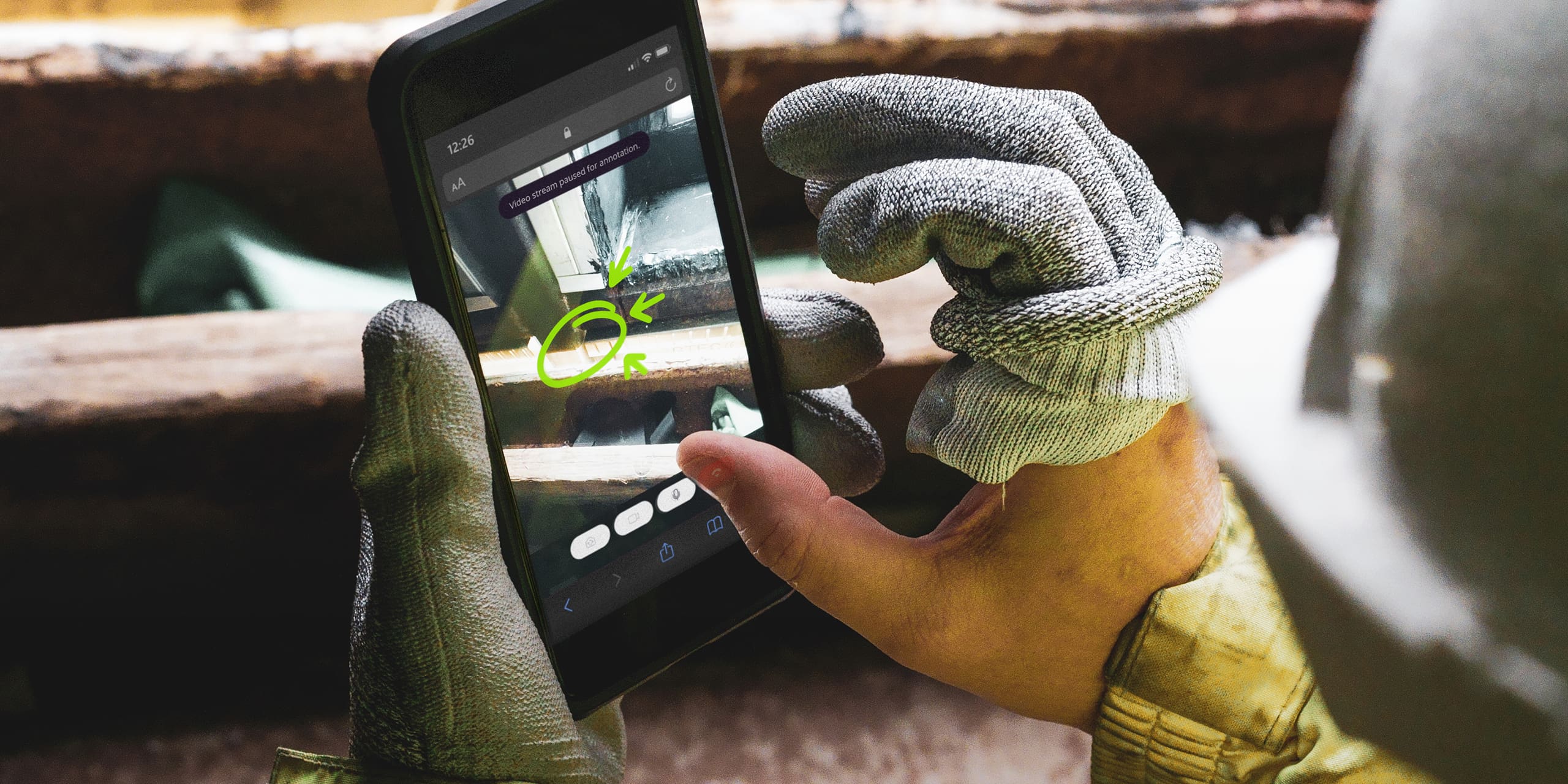

mXassist is a virtual reality assistant that combines cutting-edge Augmented Reality (AR) and Artificial Intelligence (AI) to support your frontline workforce. Automated guidance helps to accurately identify products, diagnose faults and rapidly resolve issues to improve first time fix rates and operational efficiency.

You can give your workforce the support they need in an easy to understand, accessible platform and transform the way they work.

- Make it simple to diagnose and repair complex or new faults

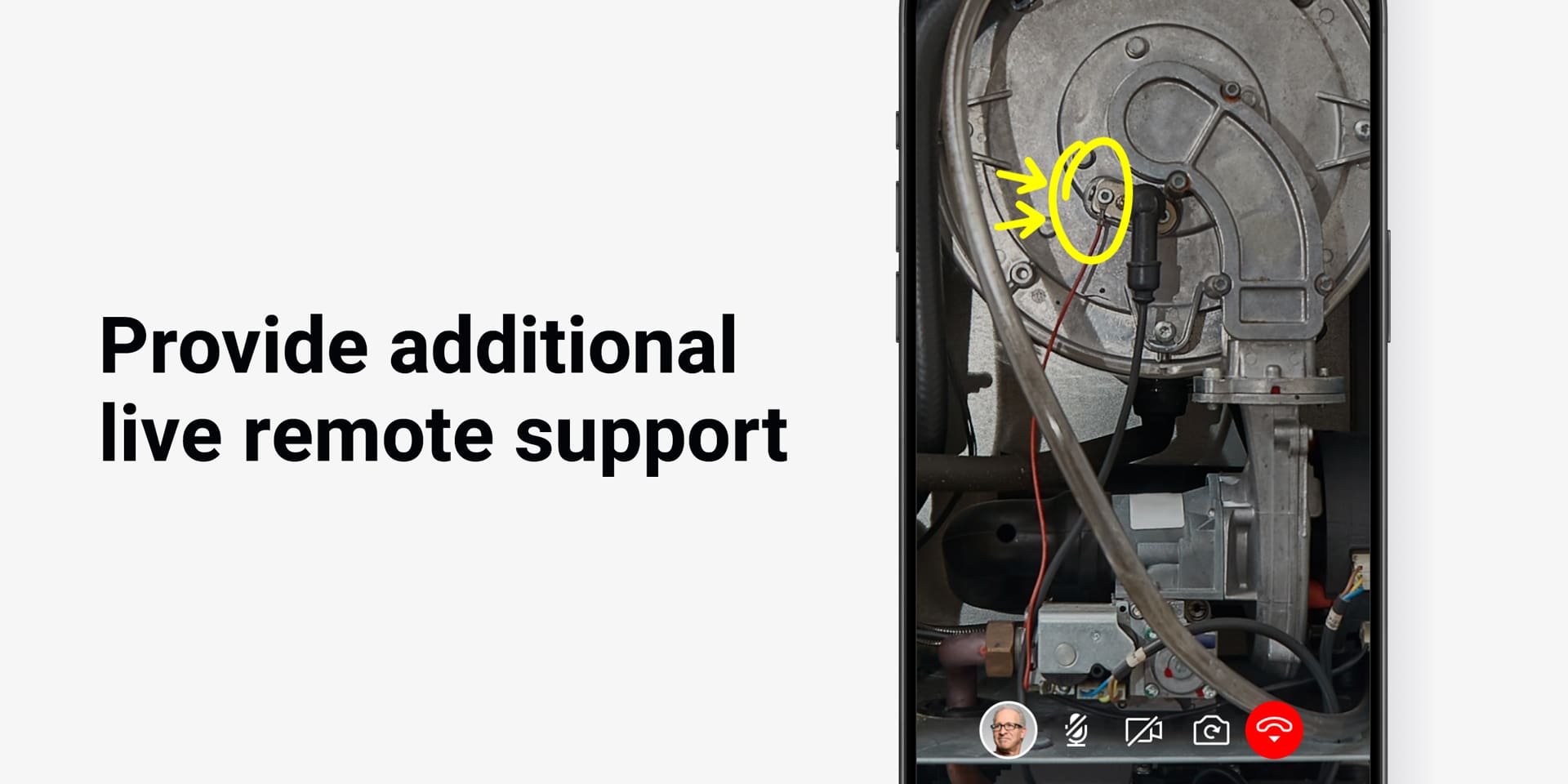

- Deliver additional online, live support when needed

- Improve first-time fix rates

- Reduce operational costs

- Train new recruits

Let mXassist help you

Empower your field technicians and give them the knowledge they need to successfully complete their job. With mXassist they will become an instant expert with AR overlays and AI insights.

Contact us

Taking the leap from traditional ways of working can be hard, that’s why we are here to help.

Our team will develop the right solution for your business, by ensuring that we are meeting the specific challenges that you face, whether it’s increasing machine uptime, enabling better system data visualisation or fewer engineer visits to site – we are here to help you.

Bespoke systems development ›

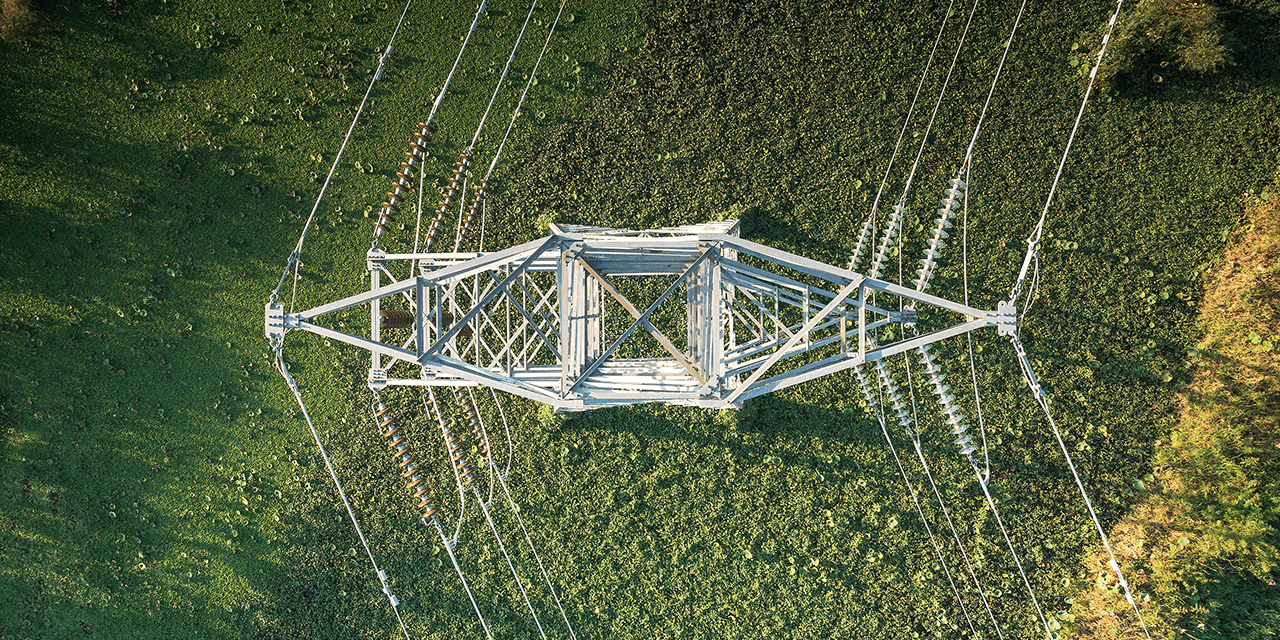

Bespoke systems development › Power and utilities ›

Power and utilities › Oil and gas ›

Oil and gas › Defence and aerospace ›

Defence and aerospace › Engineering and manufacturing ›

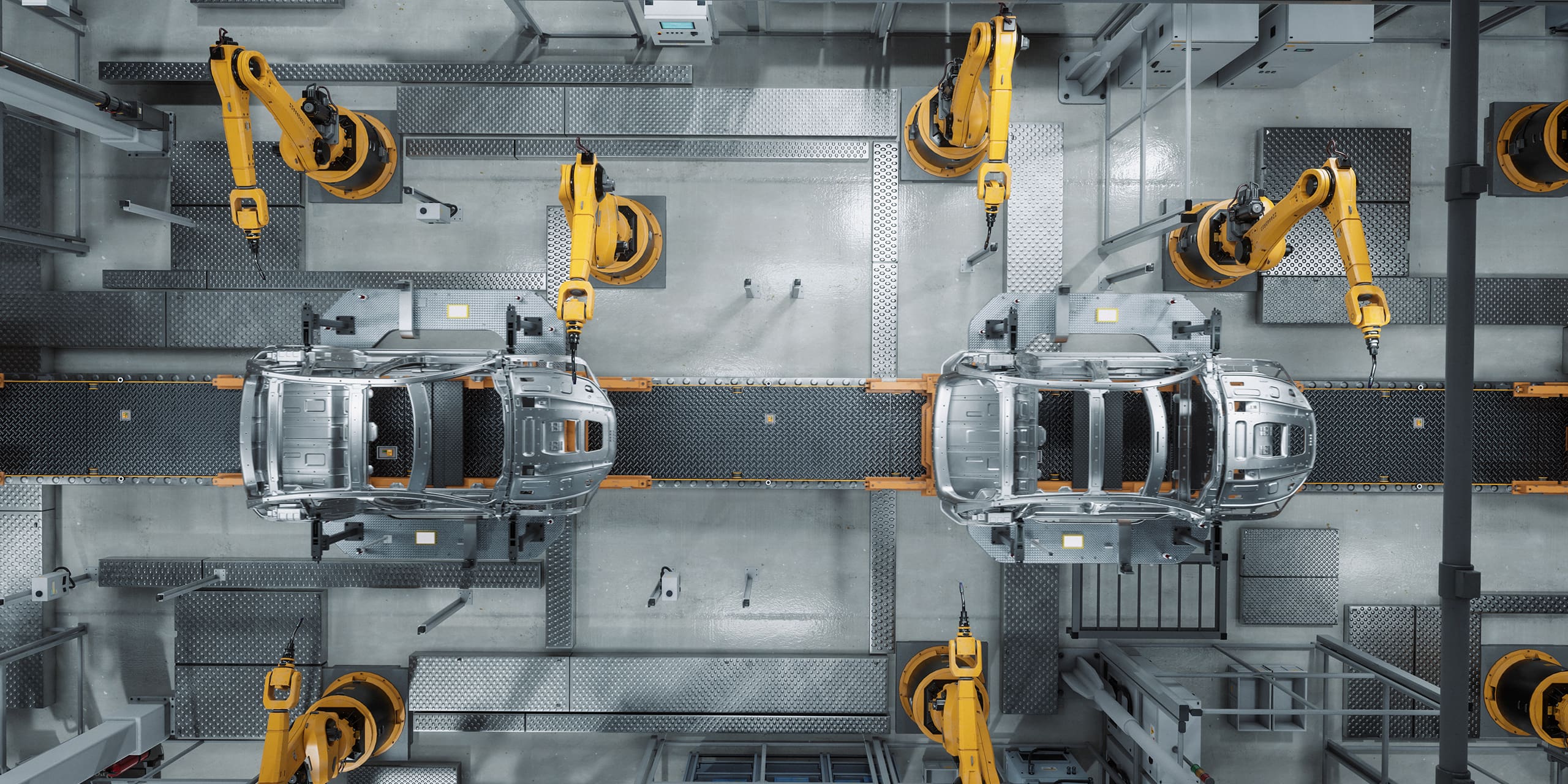

Engineering and manufacturing › Case studies ›

Case studies › Videos ›

Videos › Augmented Reality ›

Augmented Reality › News and insights ›

News and insights ›