Are you managing business data across multiple platforms, formats and sites? Do you struggle to gain actionable, intelligent insights from your data? Could your asset management be more efficient?

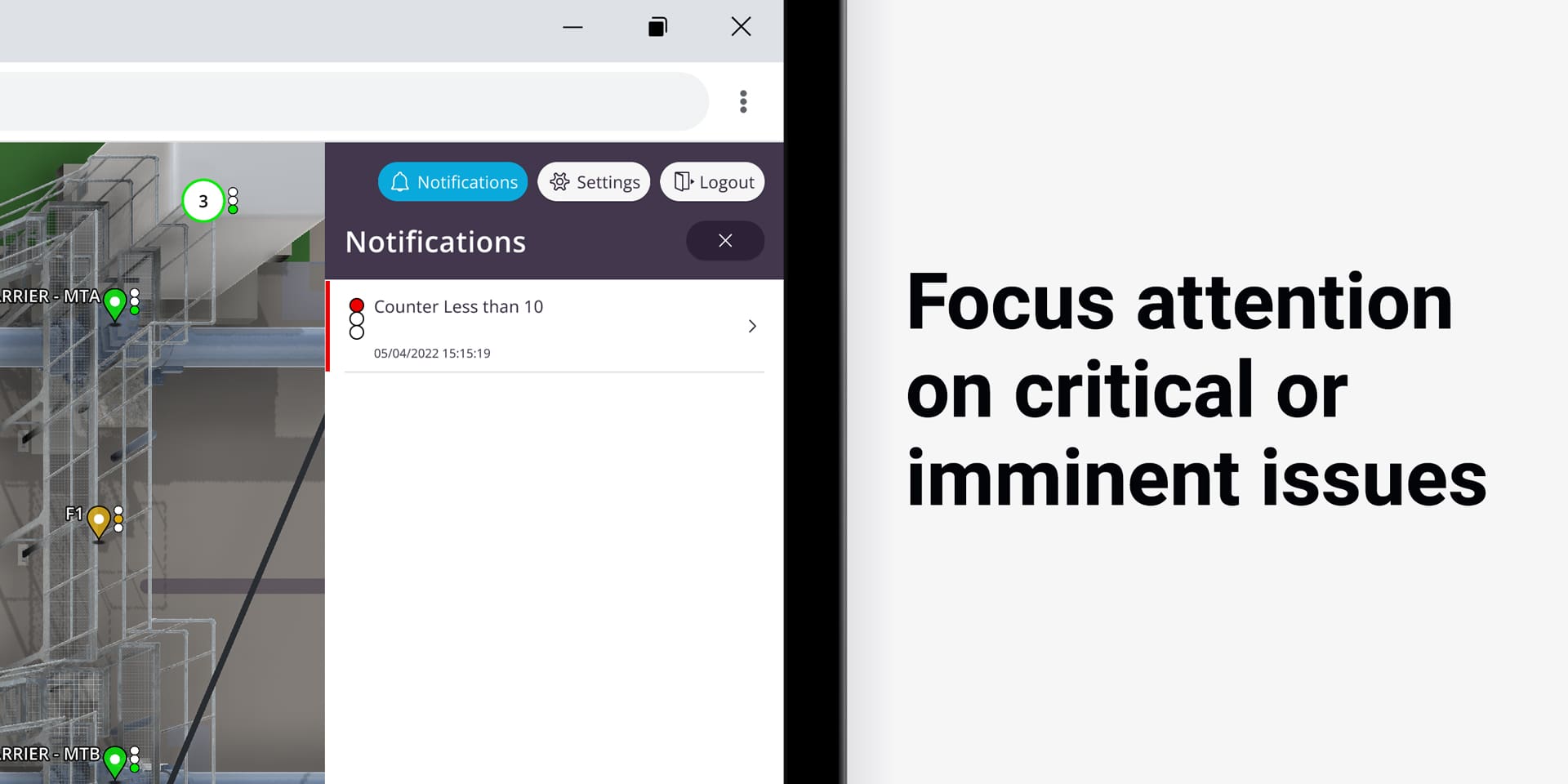

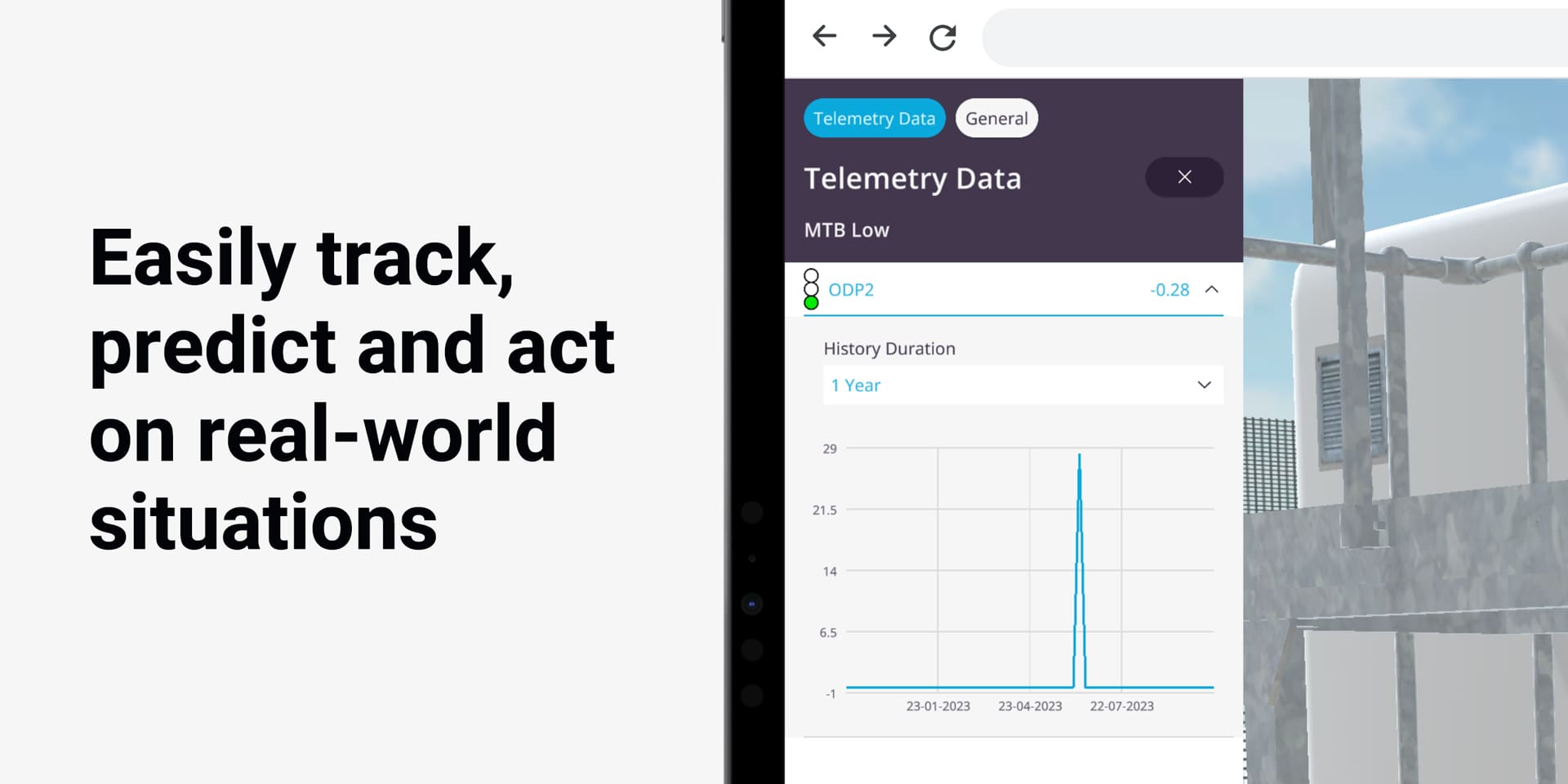

The best decisions are made using data, but your data is only as good your ability to visualise, contextualise and process it, so you can respond to changes quicker and better predict future scenarios.

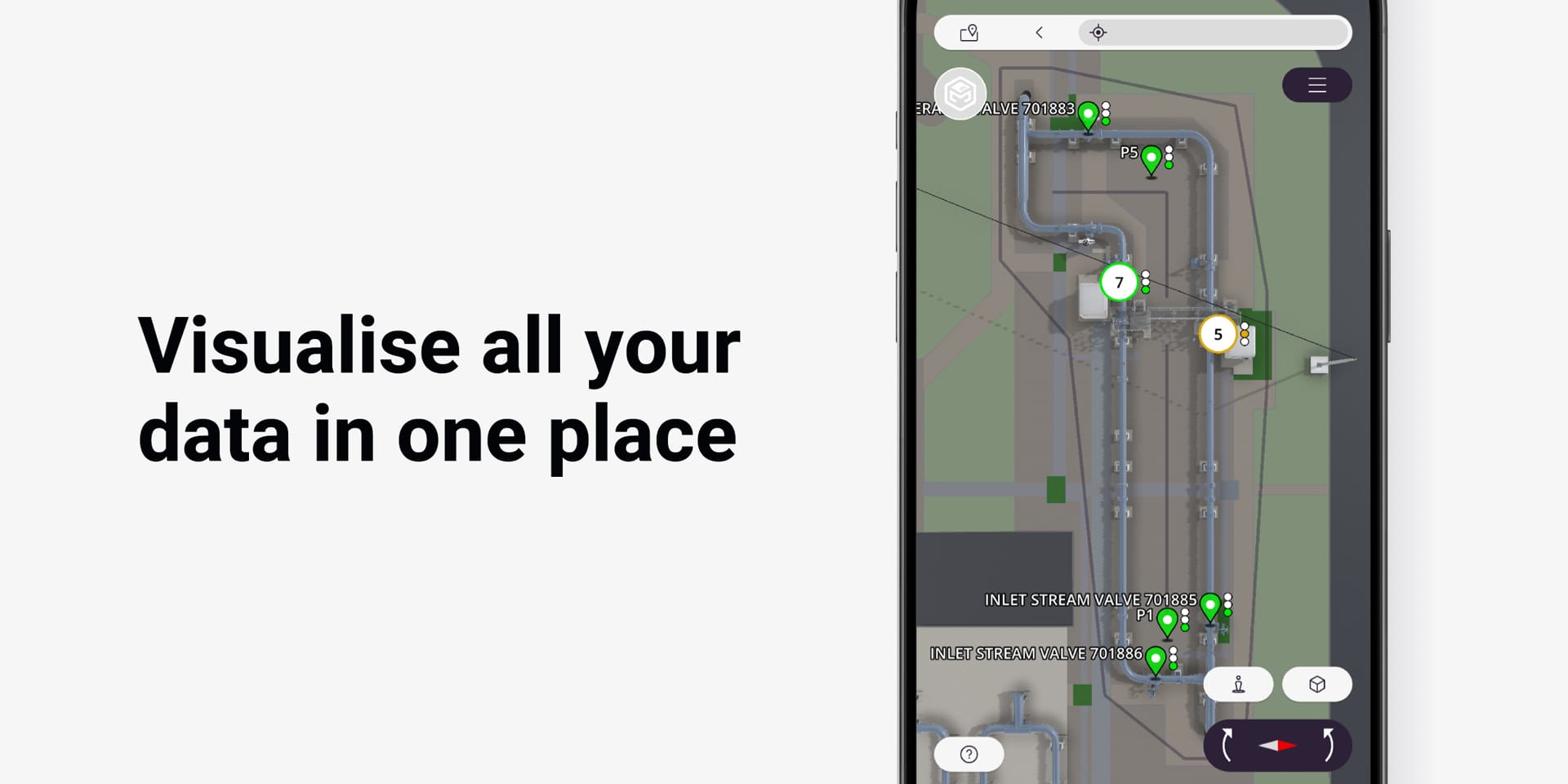

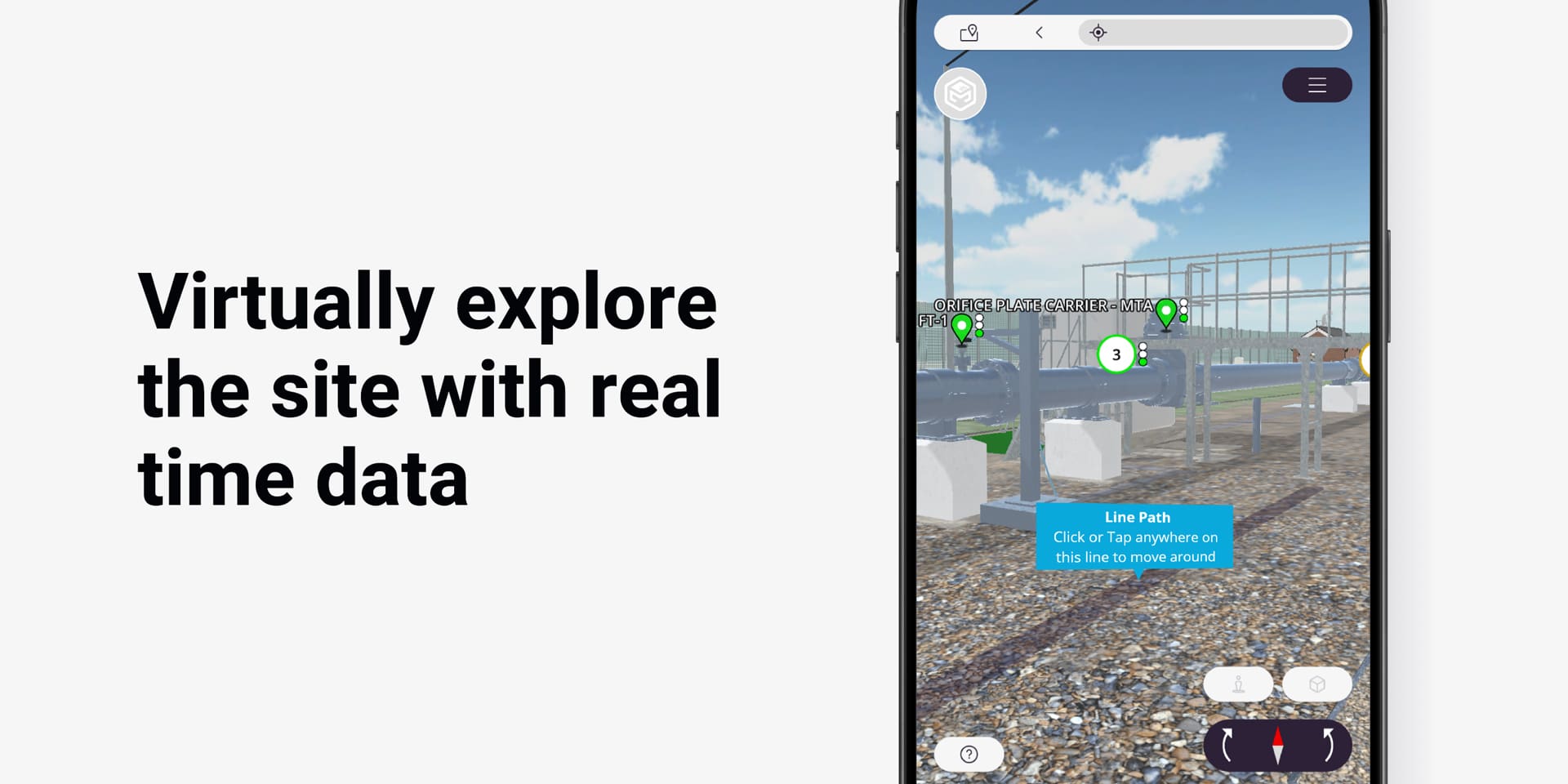

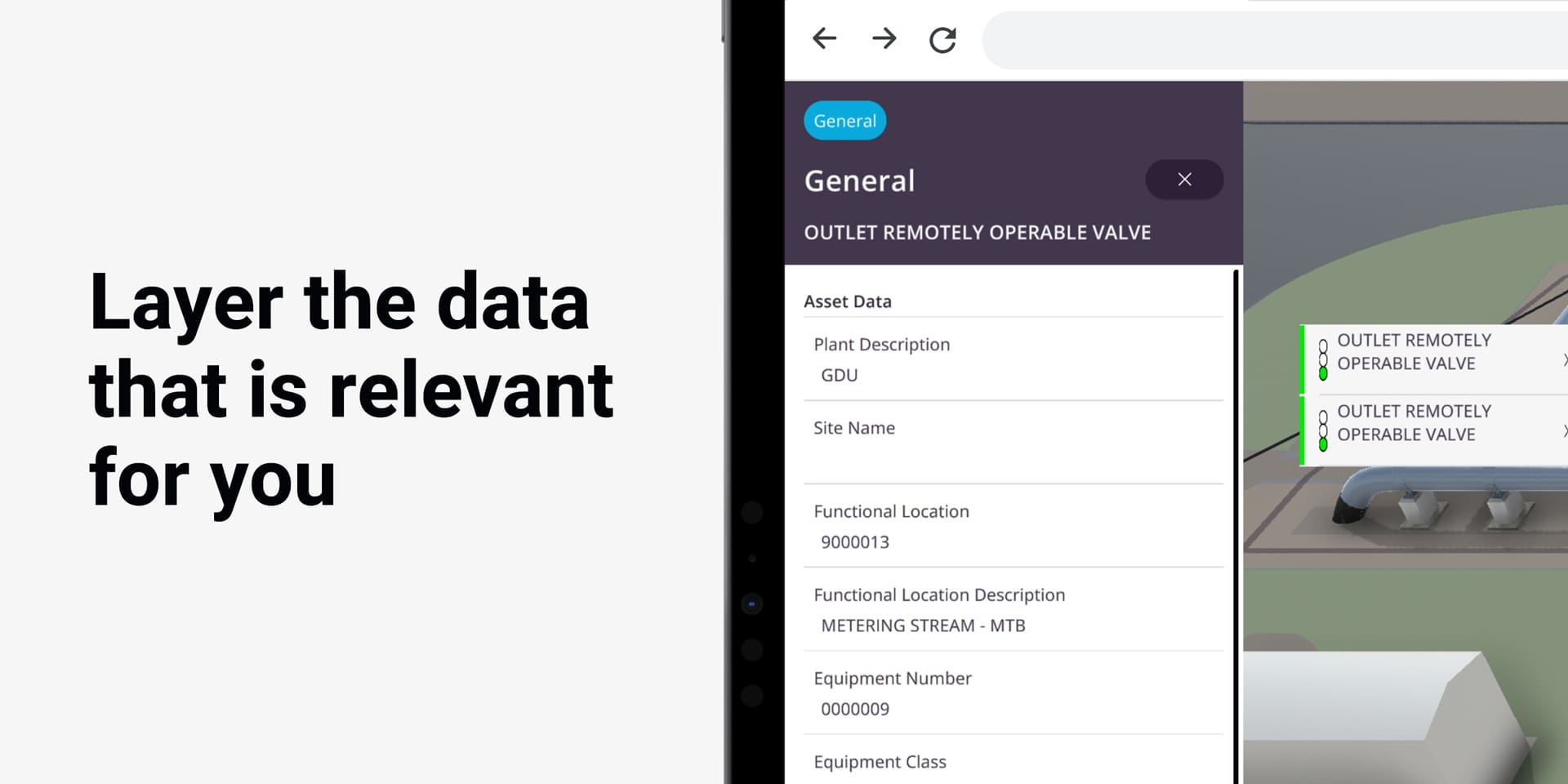

Using a dynamic 3D digital twin mXvision will visualise and merge your information in the metaverse including Geographic Information System (GIS), Building Information Modelling (BIM), SCADA, PLC IOT and telemetry. mXvision is one ‘single source of truth’ that is easier to understand at various levels.

- Unlock a digital transformation across your organisation

- Create a collaborative, accessible, intelligent platform

- Monitor and analyse your information

- Improve decision making

Visualise your data with mXvision

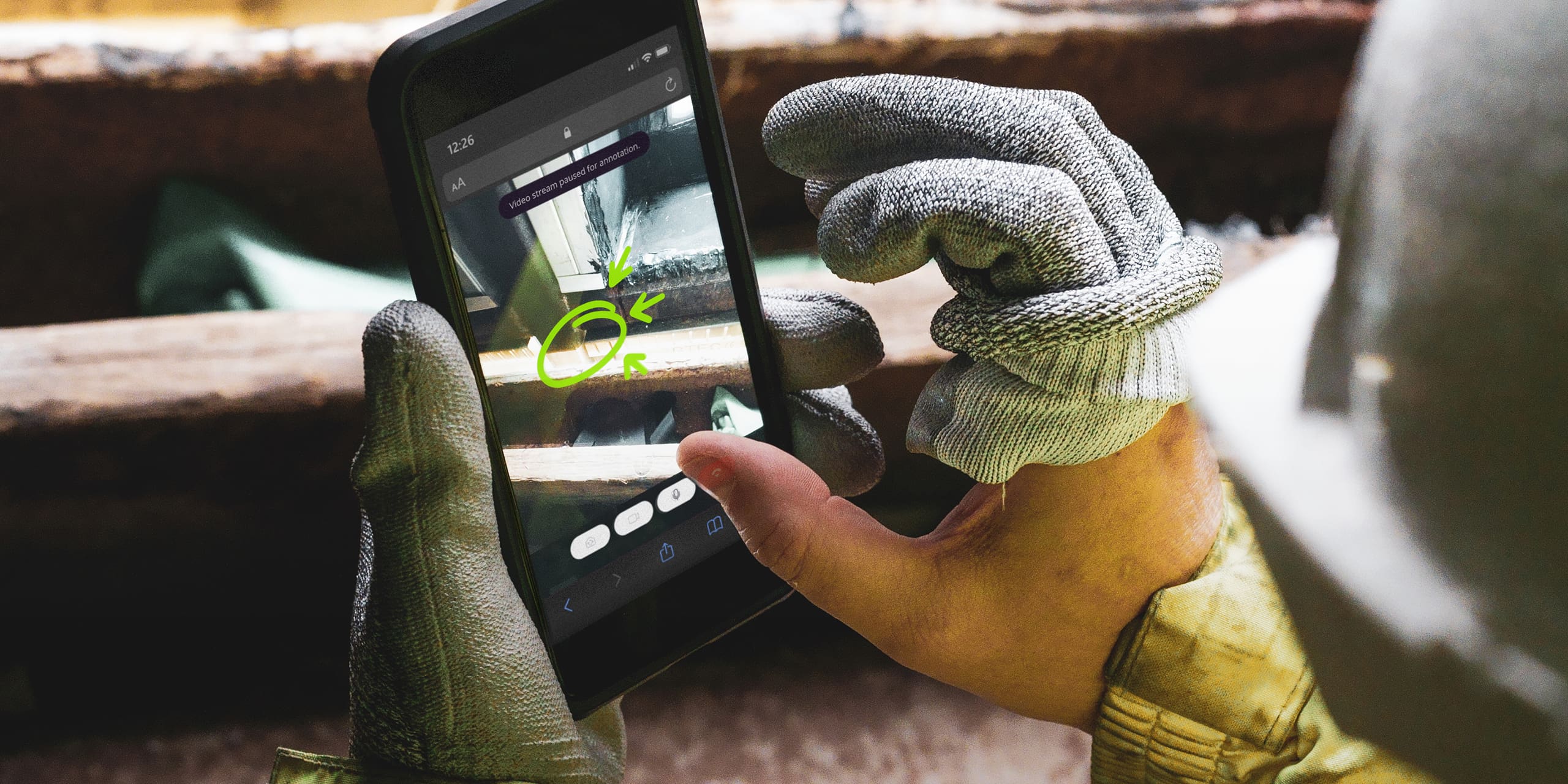

3D visualisations of sites and assets are presented in virtual reality and augmented reality and then integrated with ‘real-time’ data.

Want to find out more?

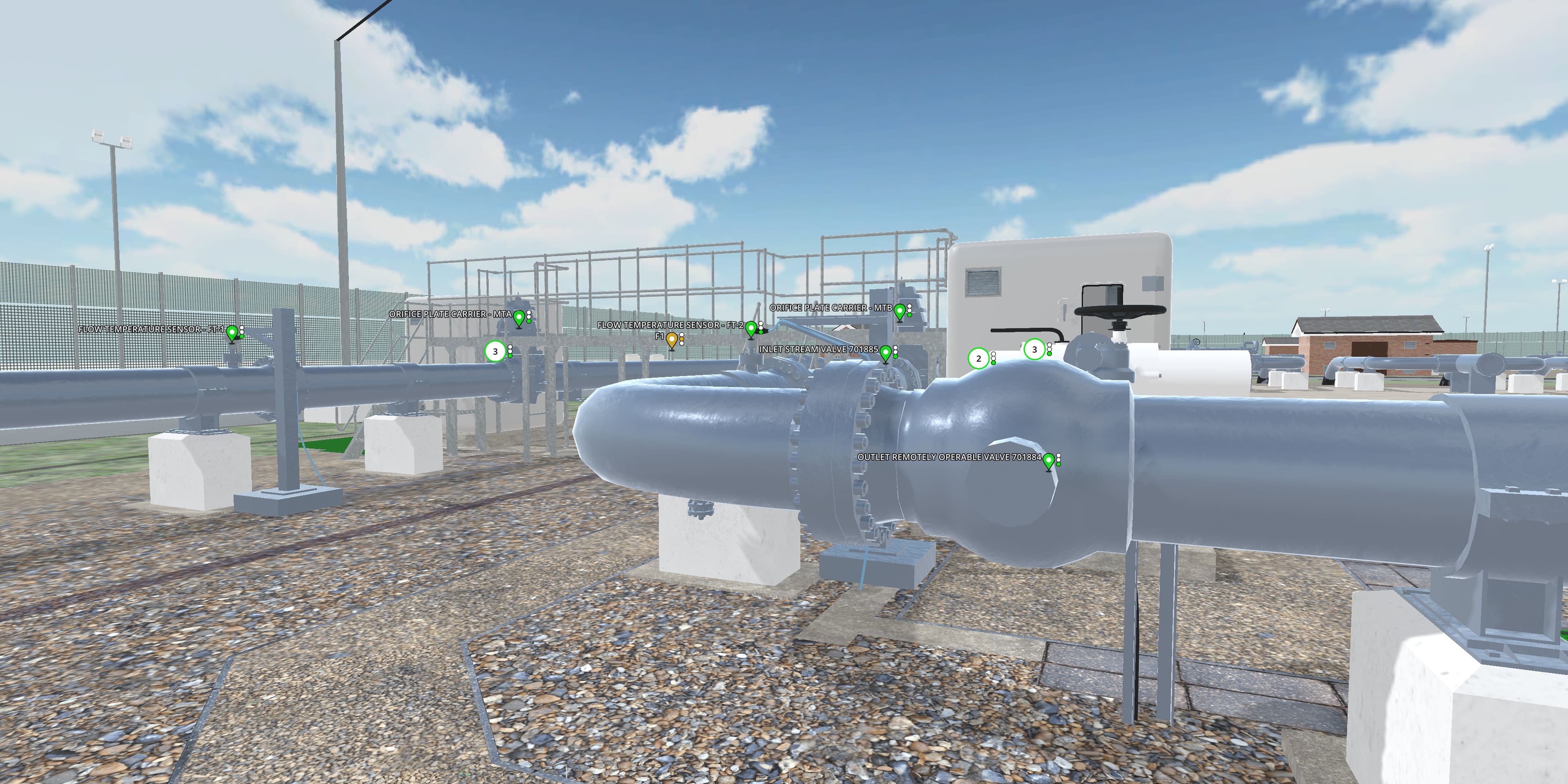

Cadent Gas keeps at the forefront of innovation with real-time 3D digital twin

mXvision helps Cadent’s workforce to remotely monitor, visualise and interact with ME/2 telemetry and IoT data in a dynamic 3D environment for better decision-making.

Download case study ›

Contact us

Taking the leap from traditional ways of working can be hard, that’s why we are here to help.

Our team will develop the right solution for your business, by ensuring that we are meeting the specific challenges that you face, whether it’s increasing machine uptime, enabling better system data visualisation or fewer engineer visits to site – we are here to help you.

Bespoke systems development ›

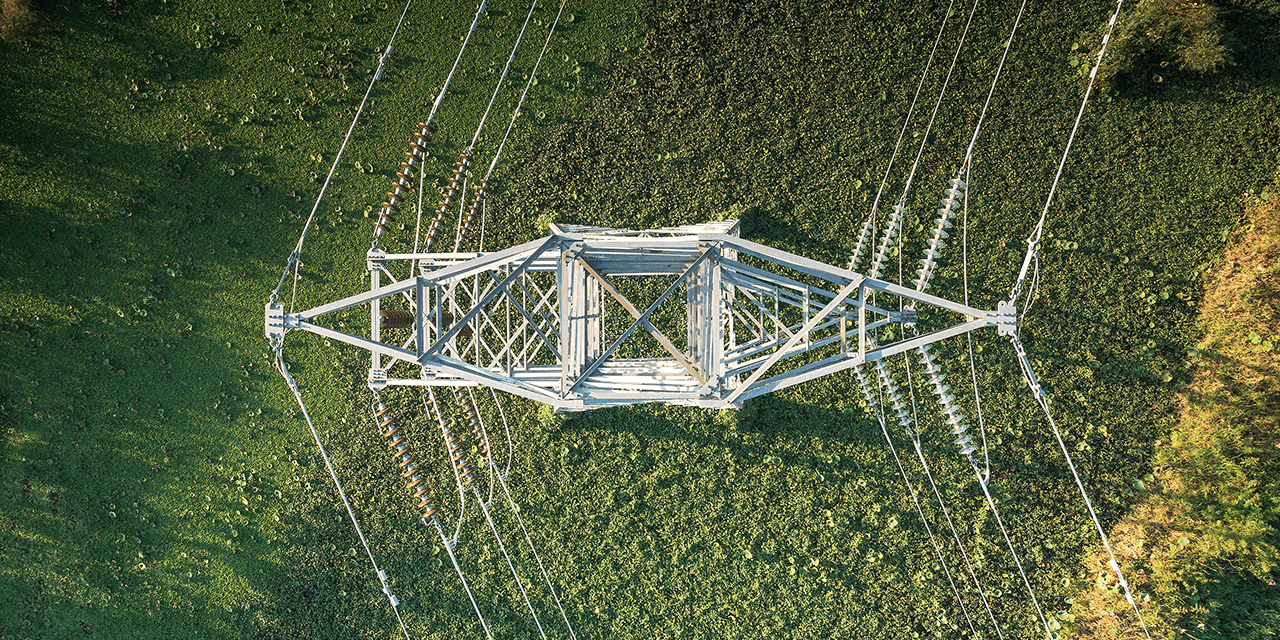

Bespoke systems development › Power and utilities ›

Power and utilities › Oil and gas ›

Oil and gas › Defence and aerospace ›

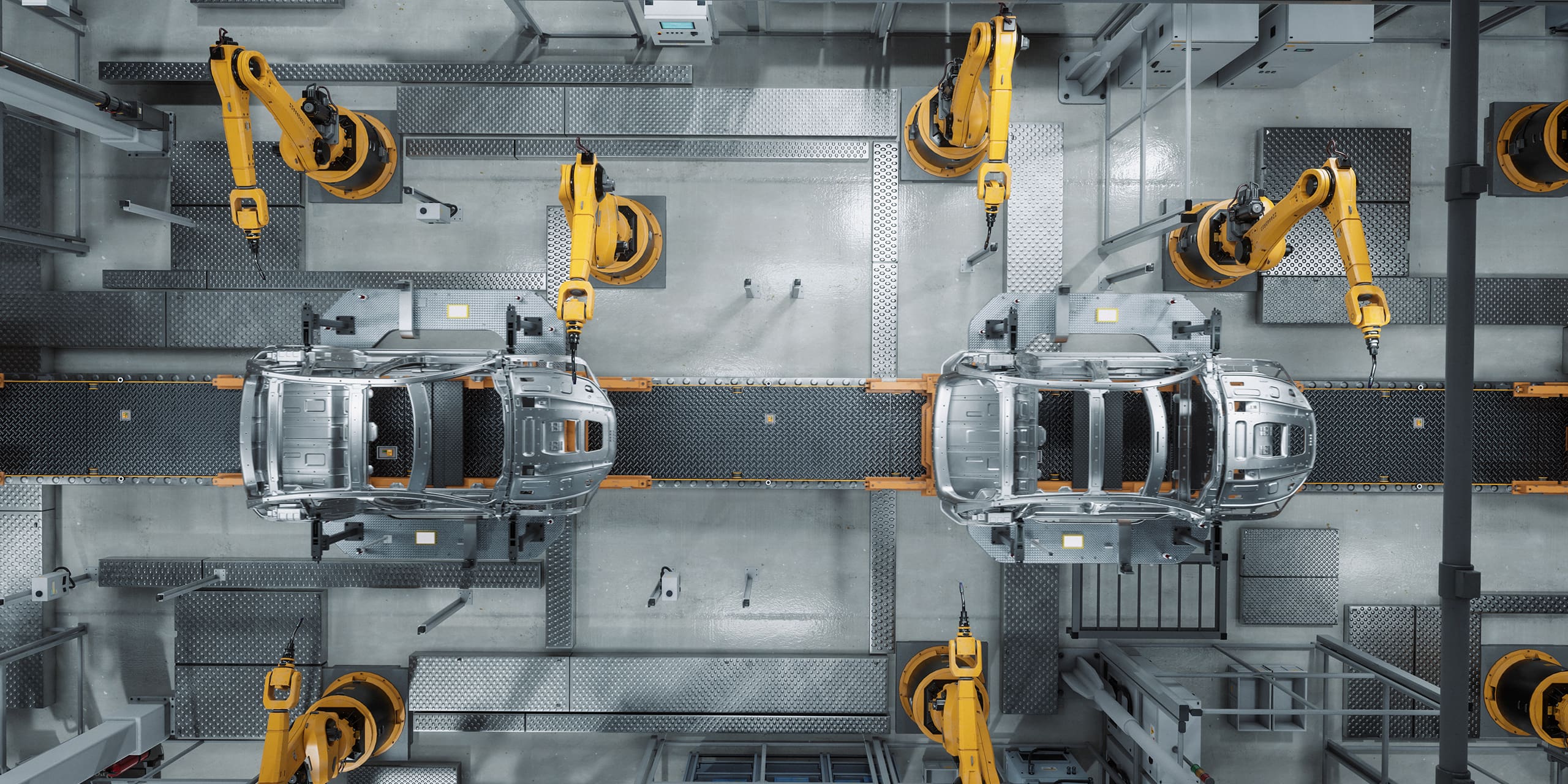

Defence and aerospace › Engineering and manufacturing ›

Engineering and manufacturing › Case studies ›

Case studies › Videos ›

Videos › Augmented Reality ›

Augmented Reality › News and insights ›

News and insights ›